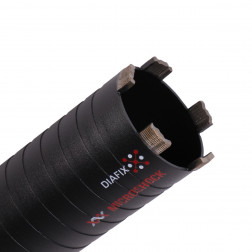

Core drills

37 modelsCHOOSING OF DIAMOND DRILL BITS

A diamond drill bit is the most effective tool for making holes in various construction and finishing materials. It easily copes with drilling bricks, concrete, reinforced concrete, ceramic tiles, and granite.

But one type of drill bit cannot effectively drill all materials equally well. Therefore, there are many types of diamond drill bits, depending on the material being processed and the equipment on which it is used.

LIFETIME

The number of holes, that a diamond drill bit can perform until the diamond-bearing layer is completely worn out, primarily depends on the following factors:

- the level of strength, hardness, abrasiveness, and reinforcement (for concrete) of the processed material;

- the power of the drill, hammer drill or drilling machine used;

- drilling conditions and modes (with or without water, RPM);

- optimal choice of drill bit design, the cutting characteristics of which must meet the above operating conditions.

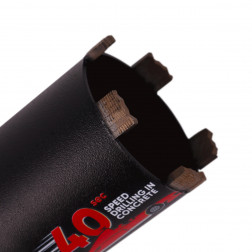

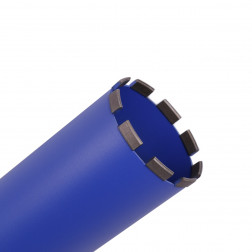

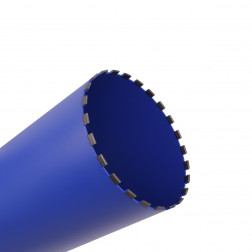

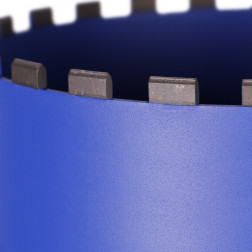

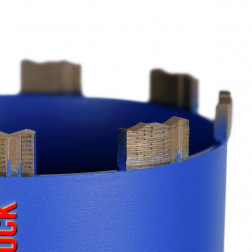

The right choice of a diamond drill bit according to the type of welded segments.

The soft segment (RS) should be chosen when processing hard materials (reinforced concrete).

The medium hardness segment (RM) is versatile and will cope with most construction materials.

The hard segment (RH) will be the best choice when drilling abrasive materials.

Incorrect choice of a segment can lead to premature wear of diamond drill bit segments or, conversely, to too low drilling speed.

THE RIGHT CHOICE OF DRILLING TOOLS

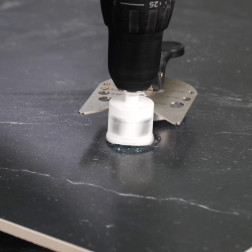

Drilling with large diameters of diamond drill bits requires powerful equipment (2-5 kW) and a constant supply of water. When drilling indoors (especially after finishing repairs), there is often a problem with contamination of the work area. In this case, an effective solution would be to use an AquaDUSTER (™ MECHANIC) type device for removing dust and wet sludge, which is connected to an industrial vacuum cleaner.

For drilling without cooling, it is recommended to use a drill or a hammer drill with a power of at least 1.2 kW or special drills with micro percussion, which guarantee high drilling speed even on durable concrete grades.

Various devices connected to the vacuum cleaner are used to remove dust during dry drilling. For shallow drilling (under sockets), the optimal solution is to be used devices such as FixDUSTER and DrillDUSTER (™ MECHANIC). In the first case, drilling can be performed without a centering drill bit.

For dust removal during deep drilling, special adapters are used, mounted on the drill shank and also connected to the vacuum cleaner. Dust extraction is carried out through the drill bit's inner hole and the hollow shank. Such adapters sometimes can be included with a drill or purchased separately (DrillSTREAM in ™ MECHANIC).

COMPLIANCE WITH THE RULES OF USE

Compliance with the drilling recommendations from the producer of diamond drill bits is the key to a long service life of the tool.

Ultimately, many factors can affect the resource and performance of diamond drill bits: temperature, humidity, heterogeneity of the same material, drilling methods (vertical, horizontal, at an angle), which makes very variable the lifetime of each tool.