Diamond blades for Wall chaser

5 modelsThe design of modern interiors excludes the presence of electrical and plumbing communications in an open form. A special niche, named groove, is cut out to get this effect. Often, the strobes are make using an angle grinder with subsequent processing with a hammer drill. The most effective is the use of wall chaser. Due to such equipment, the cutting of grooves is significantly accelerated, minimized construction waste, and the accuracy and parallelism of cutting exceed any expectations.

Wall chasers can be divided into 2 categories: home and professional use. Home is designed based on an angle grinder, but professional ones are structurally a different power tool, which is much more powerful and larger. All of them are used with a vacuum cleaner in fact, that a lot of dust is formed when cutting construction materials, especially if you simultaneously work with two diamond blades. The equipment market offers a massive range of wall chasers, which much different in their characteristics. However, the fundamental parameters that should be focused on are two:

- The diameter of the mounting blade. On the wall chaser can be used a diamond blade from 125 to 230 mm in diameter. The larger the size of the consumable to be mounting, the deeper chasing can be made. Due to the 125 diameter blade, it is possible to perform a groove up to 40 mm depth, with a 230 mm blade – up to 65 mm.

- Wall chaser power. This parameter can range from 0.8 kW up to 3 kW, depending on the design, brand, and diameter of the mounting blade. The more powerful the equipment, the higher the processing speed of the material.

Chasing is made on materials, that can be radically different due to processing level. On durable materials, such as concrete or reinforced concrete, it is better to use more expensive, professional blades. For light (abrasive) materials, like brick, aerated concrete, cinder block and others, you can use a cheaper blade from home series. However, it is worth remembering, that abrasive construction materials wear out diamond tools much faster, therefore, with large volumes, it is better to find a blade with a high resource.

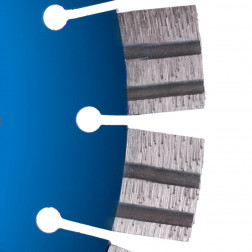

When cutting grooves, diamond blades are constantly in a blind cut. Because of this, they get very hot. In case of long heating, in the diamond-bearing layer of a blade with a continuous layer (turbo), may form cracks. Therefore, it is necessary to use segmented blades. The design of the blade's body provided the sectors so that the body can expand during prolonged heating, without destroying the diamond-bearing layer. That is why it is more expedient to use a segmented diamond blade when chasing. One of the main advantages of segment blades is that diamond segments can be welded onto a hardened body, which has greater resistance to loads than conventional. During prolonged work in a blind cut, an unprepared body may begin to lose its rigidity, and the cut will begin to lead away. Based on this fact, the best blades for wall chaser are segmented with a hardened body.

Did you know that you can make a budget wall chaser with any 125-diameter grinder? Especially for this purpose, the “AirChaser 115-125” device has been developed in TM “Mechanic”. This device is an open-type casing, that is mounted on any angle grinder. Furthermore, you still have the cutting overview. You can connect a vacuum cleaner to this device using a special nozzle, and take away almost the entire volume of formed dust. The kit includes a special spacer that allows you to install diamond blades parallel to each other, and several plastic washers to adjust the cutting width. Simultaneously, plastic wheels provide movement on any processed surface.

You can easily choose diamond blades for a wall chaser of any diameter on our website. Experienced consultants will be able to help you select the tool for the required goals.