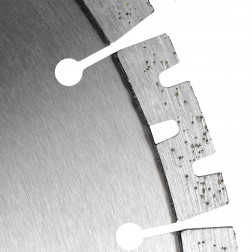

Diamond blades for Petrol saw / Electric saw

14 modelsCutting concrete, bricks and other construction materials is a widespread operation on construction sites. However, not all such kind of work can be done with an angle grinder because a diamond blade for a 230 angle grinder can deepen by about 65-70 mm, which usually is not enough.

In addition to insufficient depth, we are faced with a large amount of dust, due to the fact, that it is not allowed to work with water supply on such electrical equipment.

Diamond cutting of construction building materials with the gasoline cutters and wall chasers greatly simplified the performance of this kind of work. It allows you to cut to a depth twice as deep as the angle grinder, and thanks to the water supply, you can minimize and localize construction waste.

A power cutter is autonomous equipment, that can be used on open construction space or for road works, but indoor operation is prohibited due to exhaust gases. Thanks to them, it is possible to perform cutting, both in manual mode and on a floor-mounted movable adapter.

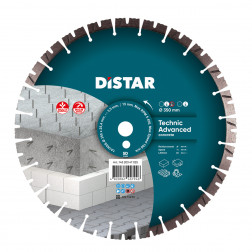

The electric cutter is best suited for indoor work. This is a very light (up to 8-9 kg) type of equipment, designed to work only in manual mode. Diamond blades with a diameter of 300 and up to 450 mm are used on power and electric cutters, it allows cutting to a depth of up to 150 mm. The blades with a diameter of 350 mm are the most widespread.

The work takes place with a constant supply of water, so we completely exclude dust formation. After cutting, we need to remove the sludge only (a mixture of dust and water), which is localized at the cutting place. Using an electric and a power cutter, the following tasks are most often performed:

Cutting of door and window openings.

Cutting of floor slabs.

Cutting openings or hatches in floor slabs.

Trimming the foundation or facade.

Dismantling of overall structures.

Cutting of temperature and deformation seams.

Cutting for various communications.

Floor renovation.

Dismantling of the road surface.

Cutting of various construction materials, such as concrete, brick and others.

This is a list of the most common tasks that can be performed on power or electric cutter.

To choose the right diamond blade to perform the work, two main factors it is worth considering:

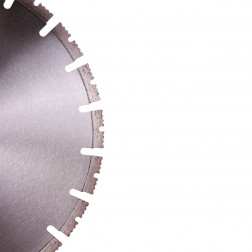

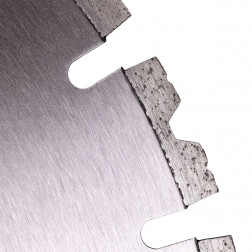

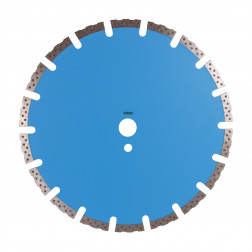

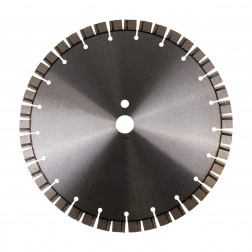

Processed material. When cutting highly abrasive materials like brick, foundation block and others, we can take almost any blade because these materials are easy to process. One of the exceptions is asphalt: this material requires a specialized blade, since its abrasiveness has a big effect on the resource. Diamond segments of increased hardness with an increased number of diamond crystals are used in asphalt blades. It provides the blade with high service life. In addition, the blade is often equipped with protective segments, that prevent wear of the blade body. For more durable materials of medium and low abrasiveness such as hard reinforced concrete of high grades, or granite, use the corresponding diamond blade. Such blades have a durable, hot-tempered body and a soft metal segment bundle, which allows processing of hard materials with high productivity.

The power of the equipment. The higher the power of the electric or the power cutter, the more high-quality diamond blade must be chosen. Due to the high power of the equipment, the maximum processing speed of the material is achieved, which entails an additional load on the blade body. Diamond blades can be made from ordinary or hardened steel. If non-hardened blades will be using on powerful equipment, most likely, the body will lose its rigidity and the cut will begin to lead away. The straightness of the cut decreases, and because of this the body experiences additional loads. Additionally, the cutting speed is significantly reduced. When working with a more expensive diamond tool instead, which is made on a hardened body, this problem is excluded because such a body has a margin of strength and can withstand heavy loads.

The symbiosis of good equipment and high-quality diamond consumables will allow you to perform a wide range of construction work with high speed and minimal cost.

On our website, you can not only buy a diamond blade, but also get high-quality advice on the choice of a cutting blade.

Consultants will help you to choose a diamond blade for power or electric cutter, paying attention to such parameters as the power of your equipment, the material being processed, and the amount of work performed.