Diamond blades for Stone cutter

4 modelsVarious natural and man-made materials such as marble, granite, sandstone, concrete and many others, are very common when creating interiors and exteriors.

It is very difficult to perform precise cutting of such materials manually (for example, with the angle grinder), so professionals use other equipment, such as a stone cutter (stone cutting machine).

These machines allow you to cut various hard types of stone quickly and efficiently. Cutting on them is carried out with the diamond blades. They must be chosen accordingly for the processing material.

The main advantages of stone cutters are straightness, processing speed, and a large cutting depth (in comparison with an angle grinder). The main disadvantage is a more professional service to maintain accuracy and quality when cutting. Stone cutting machines are divided into 2 subgroups:

- Professional. These are large industrial devices, that are powered by 380 V (less often 220 V). They are used for cutting large-sized stone slabs.

- Semi-professional. Compact machines, that operate from a 220 V and are used on almost any construction object. Now we will talk about them, due they are widespread.

Frequently, a semi-professional stone-cutting machine is a compact and convenient type of equipment for transportation. It is used for cutting various types of stone with a relatively small size, due to the small size of the table (up to 1.5 m).

Cutting is carried out only with the supply of water, which serves as effective cooling. The most common stone cutters are used with blades 350 mm in diameter. Almost all of them can perform cuts from 45 to 90 degrees to a depth up to 110 mm. Cutting can be carried out in several ways:

- Lowering the cutting blade onto the material. With small dimensions of the workpiece, we can fix it on the table and cut through by lowering the rotating diamond blade, until it is completely cut.

- Feeding the workpiece to the blade. Any stone cutter has a table, moving along the guides. Thus, we can lower the blade to cut the depth we need, and push the table together with the workpiece to the blade.

- Combined. This type of cut is applicable for larger and thickened materials. At first, we cut to a certain depth, and then lower the blade deeper. After several such passes, we completely cut off the workpiece. This method is most often used to achieve maximum cutting accuracy.

The choosy blade for a stone-cutting machine is extremely important. To make the right choice of diamond blade, you need to pay attention to the following factors:

- Processed material. Due to the range of processed materials on such a machine being wide, it is necessary to have a diamond blade for the appropriate material, such as granite, brick, paving slab or other material. Most craftsmen, who are constantly engaged in stone processing, have several blades. They do not cut concrete by blade for granite or vice versa in no case.

- Scope of work. For the same types of material, you can find several blades, even from the same manufacturer. This is due to the different technical characteristics of the blades for various tasks on the required material.

- The need for finishing cutting. Cutting of any material can be divided into finishing and roughing. Rough cut is one, that will be hidden in the future, or placed in places, where it does not matter at all. Finishing cutting is used for the processing of facing materials, which will be the face of the object in the future. Diamond blades that perform a fine cut, are always more expensive, so when choosing a blade you can save money, if the clean of the cut is not important to us. And vice versa, if we want to achieve the cleanest edge possible, we need to take a more expensive blade.

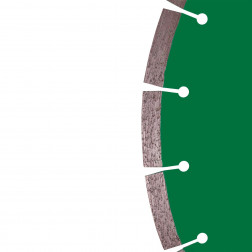

Stone-cutting machines use 2 types of diamond blades: continuous and segmented edge. Diamond blades with continuous edges are thinner and excellent for precise and fine cutting of facing materials.

Segmented blades, due to their discontinuity, are used for rough cutting of materials.

On our website you can easily pick up diamond blades for a stone cutting machine of any power and size. Our salesman will help you decide which blade will be the best solution for cutting every type of stone.