Diamond blades for Petrol saw

7 modelsAlmost any repair of the road surface involves the use of equipment, such as a floor saw. This is a relatively compact type of professional equipment for cutting various construction materials.

Due to it, many operations are proceeded, both indoors and outside. Diamond blades for a floor saw as a cutting tool are used, with diameters from 350 to 800 mm.

There are many models of this equipment on the market, which may differ in several main criteria:

- Engine type. The floor saw can work on gasoline, diesel or electric engine. The fundamental difference between electric is that it does not emit exhaust gases, and can be used indoors.

- The mounting blade size. According to this parameter, they can be divided into 3 subgroups: small (up to 500 mm), medium (up to 800 mm) and large (up to 1200 mm). The diameter of the diamond blade affects the cutting depth, so for some tasks we need a small cutter, and for others – we must take an average one.

- Type of drive. According to the type of drive, they are divided into manual and self-propelled. The manual floor saw is moving and cutting by the worker's power, instead the self-propelled one moves automatically, the worker just adjusts the speed. It is better to use a more professional blade for a self-propelled floor saw, due to the engine power is often much higher, than that of manual ones.

Any type of floor saw, regardless of the type of engine, moves only on horizontal surfaces due to its weight. Cutting of any kind of material is carried out only with the supply of water, since the diamond blade is in a blind cut and gets very hot.

Many different tasks are performed during construction due to the floor saw, that can't be performed with other equipment:

- Dismantling of floors, ceilings and foundations.

- Cutting of grooves for communication.

- Cutting openings in slabs.

- Cutting of deformation seams on runways.

- Temperature and technical seams.

- Removal of old asphalt or concrete road surfaces.

All these operations can be performed on different concretes or asphalt, and at different depths. Therefore, it is necessary to carefully approach the choice of a diamond blade.

For example, asphalt is a very abrasive material, and it can be cut with almost any blade, but the resource will greatly suffer. The diamond blade, which is designed to work on this material, has a much larger number of diamonds in its composition, than blades on concrete.

The most durable and highly reinforced concrete is used on runways. Cutting them is one of the most difficult tasks of industrial construction.

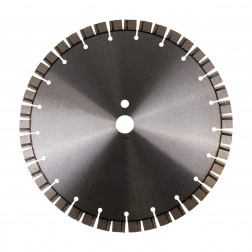

Blades for the floor saw are available only segmented and in a hardened body. The hardened body is used because the blades work under a significant load. The margin of the strength of this kind of body allows it not to deform in such conditions.

The use of segments on such blades allows them to be restored after segment wear. Restoration is the process of replacing worn segments with new ones by soldering. This procedure is performed in specialized service centers.

Instead of buying a new blade to replace the worn one, you can buy only a set of segments, that specialists will solder to you.

The resource of soldered segments for a floor saw is often slightly lower than that of laser-welded ones. However, significant savings when purchasing the segments themselves without a body will make the cost of cutting a restored blade significantly lower, than that of a new diamond blade.

You can order various diamond blades for floor saw for any materials on our website. A wide range of blades of different diameters will help you to perform construction work of any complexity. Our consultants will be able to provide information both about the purchase of a new blade, and to select segments for restoration.