Diamond blades for Angle grinder M14F

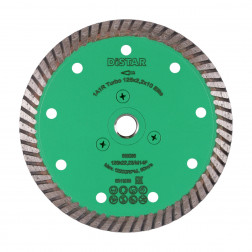

94 modelsNo renovation work is complete without cutting various types of construction materials such as concrete, brick, tile etc. The most common electric tool for performing such work is an angle grinder. And the diamond blades are consumables for the grinder. They consist of a steel body and a special diamond-bearing layer. There is a very wide range of diamond blades available, and before buying the first one it is better to study their features and scope of application, and after make a choice.

Depending on diamond blade's composition, it can process any construction material. It is important to select the right cutting blade due to achieve maximum speed, lifetime and high-quality cutting. What features should you pay attention to when selecting a diamond tool?

Diameter. For cutting of constructions materials, angle grinders 125, 150, 180 and 230 mm in diameter are most often used. Choosing the blade according to the diameter of your grinder.

Material. It is very important to select a diamond blade exactly according to the material that you will process: concrete, tile, natural stone, brick and so on.

The spindle hole. All angle grinders have a 22.23 mm spindle hole, so it is important to select a blade with exactly this diameter of the bore.

Price. If you have a small amount of work, or they do not require high accuracy and cleanliness of the process surface, it makes no sense to buy expensive consumables.

According to all the above-described features, it would be to separately note the selection of the blade by material. Sporadically, the masters ignore this point and use a diamond blade on ceramics when cutting concrete, or vice versa. This fundamentally wrong approach can lead to damage to the processed material, or the diamond layer. Even the angle grinder will carry heavy loads if you cut hard material with a blade on a soft one. Conventionally, construction materials that are processed using a diamond blade, can be divided into 3 subgroups according to hardness and abrasiveness. Abrasiveness is the ability of a material to sharpen a diamond-bearing layer. The harder the material is, the lower its abrasiveness.

Hard materials. This includes natural rocks of stones (agate, jasper, etc.), porcelain gres, granite and other low-abrasive materials. Porcelain gres is most often processed from all these types of materials, because most nowadays interiors are based on tiles. There are separate requirements for the ceramics and porcelain gres tools, since these works are finishing, therefore blades that leave a minimum of chips when cutting are very popular.

Medium level of abrasiveness. This category includes: concretes with a large and medium number of metal parts, refractory and clinker bricks, curbs and paving slabs. These materials are also very difficult to process, so they require careful selection of the blade. At the same time, there are no requirements for the cleanliness of the cutting, since most of these works are rough, and will be hidden in the future.

Soft. These are foam concrete, brick, gas block, concrete screed, asphalt and other materials with a high degree of abrasiveness. They are very easy to process, however, due to their abrasiveness, they wear out the tool a lot. Such in the previous category, there are no special requirements for the cut clean of such blades.