Grinding cups for Angle grinder Concrete

20 modelsDiamond-point cutters for angle grinders

The grinding of different surfaces during renovation work is a very common task. Often it is a roughing work because the cladding material subsequently covers the ground surface. Such work can be carried out with an industrial grinder, or with an angle grinder. An angle grinder is very handy for grinding hard-to-reach places, and we can't use an industrial grinder for sanding walls or ceilings. As a consumable for sanding building materials, diamond-point cutters for the angle grinder are used.

The process of grinding concrete and other building materials is very time-consuming and puts a lot of strain on your equipment, so you should be careful when choosing an angle grinder for such tasks. When selecting an angle grinder, pay attention to the most important parameters that will allow you to get the job done as quickly and efficiently as possible:

- Diameter of the consumables to be installed. The most popular is a 125 mm angle grinder in tandem with a 125 mm diamond-point cutter. Such an angle grinder and diamond consumables will have a minimum weight, so even walls and ceilings are easy to work with. It is not uncommon for craftsmen to use a 125 diamond cup wheel paired with a 180 or 230 mm angle grinder. Due to its greater weight compared to a 125 mm angle grinder, it stabilises the cutter in operation and significantly reduces the strain on the operator. However, working with such heavy equipment when grinding walls, ceilings or working with outstretched arms is extremely difficult.

- Power. The grinding operation, as mentioned above, puts a lot of strain on the equipment, so the use of low-powered angle grinders is highly undesirable. The minimum power for this kind of work is 1.2 to 1.3 kW, but the best option is a 1.7 kW or higher angle grinder.

- Revolutions. It is best to grind at maximum speed. The diamond tools have optimum tool life and high machining speeds at maximum linear speed. If you're looking for a 125 angle grinder, choose a model with a shaft speed of 11,000 rpm or higher.

With the right equipment, you can carry out many different grinding operations. In general, construction material processing can be divided into three categories, depending on the spatial relationship:

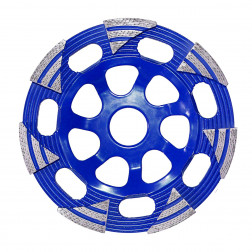

- Horizontal grinding. This includes the removal of the top layer of screed for further tiling, the removal of the overlap after formwork, the levelling of concrete floors and other floor treatment operations. When sanding floors, we don't have to put in the effort to hold the weight of the angle grinder, so these operations can be carried out with heavier equipment and a diamond consumable.

- Vertical grinding. These operations include grinding door, window and other openings, removal of surfacing after shuttering, removal of adhesive bases after tile removal and many other operations that require vertical surfaces to be treated. In this type of work, most of the weight of the equipment is shifted to the operator, so it is better to use lighter equipment and a diamond-point cutter.

- Grinding on outstretched arms. This category is the most difficult and time-consuming. We don't always have good access to the surface to be worked on, so we have to resort to grinding on outstretched arms. For this type of operation, the lightest angle grinder and lightweight, high-performance cutters are chosen.

The weight of the different cutters can vary by almost a factor of 2 (from 600 g to 300-330 g) which will be very noticeable when vertical grinding or machining with outstretched arms. In addition to weight, cutter imbalance is an important factor. If you own a car, you are probably familiar with the concept of wheel imbalance. In simple terms, this is the difference in weight at different parts of the wheel. The same phenomenon occurs with cutters. This can range from a few tenths of a gram to 10 grams. The greater the imbalance, the greater the strain on your hands and the drive of the power tool. The consequence of this is more fatigue on the handyman and a shorter service life for the angle grinder. When selecting a cutter, pay attention to whether it is marked BALANCED!

On our website you can find diamond consumables for every application - both the more durable and heavier versions for grinding abrasive materials, and very light versions for vertical and ceiling work. The sales consultant will be happy to provide information about the service life of the cutter on various abrasive materials, so that the cost of your work is kept to a minimum. And best of all, all Distar diamond tools are balanced so you're comfortable to work with!