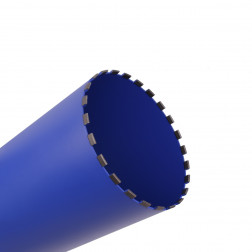

Core drills for Drilling machine 300

117 modelsDiamond drill bits for drilling units with stand

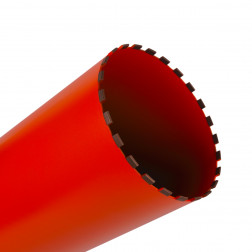

In the construction industry it is essential to drill holes in heavy materials such as concrete and reinforced concrete of various diameters up to a diameter of 600 mm. A drilling unit with a stand is used for such tasks.

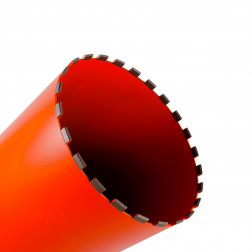

Thanks to their rigid mounting and high power, they can make holes in large diameters at high output. The consumables used are diamond drill bits for the drilling unit, which operate using water cooling.

A drilling unit with a drill stand has a number of advantages over conventional drilling and even micro-impact drilling:

- Drilling deep holes.

- Making holes with large diameters.

- No strain on the plant operator.

- High performance.

- Absence of dust sludge.

- Stand installation and drilling at any angle.

- Working with high reinforcement in concrete.

- Diamond drill bits are restorable.

All of these tasks are either extremely difficult or impossible to carry out manually without a drill stand, which is why wet drilling with a drill stand is in high demand.

One of the main disadvantages of wet drilling is the large amount of water sludge from the work. In some rooms this is not acceptable, so in order to minimise waste during drilling, a special device, AquaDuster 162, is available from TM Mechanic.

With an industrial hoover and this device, water spray during drilling can be minimised to almost zero. The tool can be used with drill bits up to 162 mm in diameter.

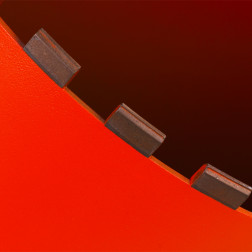

On different sites, we may encounter materials of drastically different hardness and, consequently, processing. Depending on the material, a drill bit must be selected. All building materials can be divided into 3 categories according to their hardness and abrasiveness:

Low resistance power. These are highly abrasive materials that are easy to drill, but wear out the diamond bore bit segments quickly. These can include plaster, cinder block, aerated concrete, sand-lime bricks and others.

- Middle resistance power. These materials are also processed at a very high speed, which is slightly lower than that of low-strength materials. But because they are less abrasive, the diamond drill bit lasts longer. Such materials include bricks, abrasive concrete, unreinforced concrete and others.

- High resistance power. It takes considerably longer to process these materials as there is virtually no abrasive component to help sharpen the diamond segments. This category can include fire bricks, M 400 or higher concrete, hydraulic concrete, highly reinforced concrete and others.

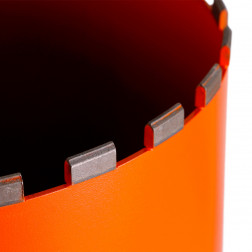

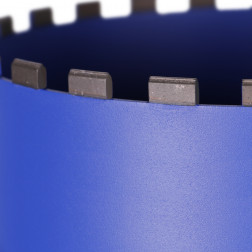

The drill bit should be selected according to the material to be drilled, as the right diamond tool will last much longer and save you money. There are several different segments in TM ADTnS which have their own advantages when processing a particular material:

- The main advantage of this segment is that it works with rebar, but it is very versatile and suitable for all materials.

- RS A softer diamond segment that has a high machining speed, but a shorter operational life than the previous one.

- RS7-X. The fastest segment that offers consistently high performance on the toughest and most reinforced concretes. Also proves to be excellent for deep hole drilling.

- RM7H. An inexpensive segment that is best suited for drilling light materials. Its main advantage is its high operational life.

Another important advantage of using wet drill bits is that they can be refurbished. Once the segments on the drill bit have worn out, there is no need to throw away the housing, as you can buy separate segments and have them soldered onto the existing housing at a service centre. This will be more economical than buying a new drill bit, and you can carry out the restoration many times over.

On the DISTAR website you can buy diamond tools, segments, various adapters and extensions, which make it possible to carry out almost all construction tasks in the diamond drilling field.

In addition to ordering drill bits and other tools, you can also get advice on their operational life and suitability and get information on which drill adapter you need for your particular drilling unit. The company's service centre will also carry out fast and high-quality restoration of drill bits with worn segments.

Drill bit diameters of 32-300 m are always in stock, and larger diameters (up to 500 m) can be ordered and received within 14 days.