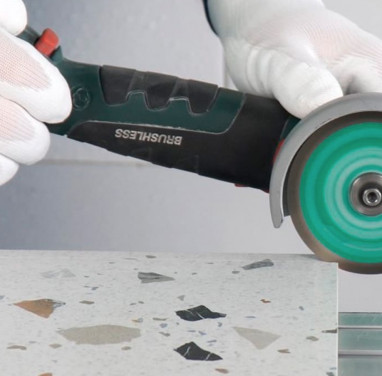

What Can Be Cut with a Diamond Blade?

For nearly 100 years, the production of a highly popular consumable material on every construction site—the diamond blade—has been evolving. Many builders ask the question: What can be cut with a diamond blade? We would like to delve deeper into the topic of cutting with diamond blades.

What Can Be Cut with a Diamond Blade?

A diamond blade can cut almost any type of construction material, including:

- Wood, plastic, steel, and non-ferrous metals

- Asphalt, brick, concrete, reinforced concrete, and hydraulic concrete

- Granite, porcelain stoneware, marble, aerated concrete, foam blocks

- Other types of natural or artificial stone

Most often, diamond tools are used for processing various types of stone, whereas their use for cutting metal, wood, and plastic is less common. Diamond blades are widely used in the following applications:

- Tile installation (cutting ceramic tiles, porcelain stoneware, and faience)

- Cladding with natural stone (cutting granite, marble, etc.)

- Brickwork construction (processing rough, facing, and fire-resistant bricks)

- Roadwork and repairs (cutting concrete and asphalt)

- Creating openings and hatches (cutting concrete, aerated concrete, foam blocks, and brick)

- Demolition work (working with plain, reinforced, and hydraulic concrete, bricks, and other artificial stones)

How to Cut with a Diamond Blade?

Aside from the question What can a diamond blade cut?, professionals often ask How to cut with a diamond blade? Simply buying a random diamond blade and attempting to cut concrete or granite is not the best idea. One of the key steps to achieving optimal performance is selecting the right blade and following simple guidelines when using the tool.

How to Choose a Diamond Blade?

When selecting a diamond blade, consider the following important factors:

- Blade purpose (which material it is recommended for)

- Compatible equipment

- Cutting method (wet or dry cutting)

- Maximum allowable RPM (rotations per minute)

For example, if you need to cut a 10 mm thick tile using a 125 mm angle grinder, you should choose a 125 mm diamond blade for dry cutting, capable of operating at 11,000-12,000 RPM (the standard speed for an angle grinder). If you need to cut concrete using a road saw, you must ensure the blade size and bore diameter are compatible with your cutter model. The blade itself should be designed for wet cutting and specifically made for cutting concrete.

How to Use a Diamond Blade?

Before starting work, check that your power tool is in proper working condition. After installing the blade, secure it tightly with a locking nut to prevent it from coming loose during operation. Before cutting, perform a test run at idle speed to check for excessive vibration, unusual sounds, and the blade’s straight rotation.

If you notice strong vibration, noise, or misalignment, reinstall the blade, ensuring that no debris is present on the supporting flange or locking nut. Also, inspect the blade itself for cracks or warping. If no issues are found during the test run, you can begin cutting!

To ensure safe, fast, and efficient cutting, follow these simple rules:

- Enter the material smoothly, avoiding sudden movements

- Do not apply excessive force—cutting should occur due to the sharpness of the diamonds, not brute force

- For wet cutting, ensure sufficient water supply to cool the blade properly

- For dry cutting, use dust extraction tools and an industrial vacuum in enclosed spaces

- When cutting metal reinforcements in concrete or brick, reduce pressure when cutting through the metal

- Secure small workpieces properly to prevent the blade from jamming when exiting the material

- Always use personal protective equipment: gloves, safety shoes, goggles, ear protection, and a respirator

Common Issues When Using a Diamond Blade

Even if you know what a diamond blade can cut and how to use it correctly, it doesn’t guarantee perfect operation. Various factors can affect performance:

- The material is too hard, requiring periodic blade sharpening

- The tool’s power is insufficient for cutting the material

- The RPM is too low, making cutting inefficient

How to Overcome These Challenges?

- Sharpening the Blade:

When cutting very hard materials (e.g., porcelain stoneware, hydraulic concrete), the diamond edges can become dull. If the material being cut is not abrasive enough to wear down the metal bond holding the diamonds, the blade will stop cutting efficiently. To sharpen the blade, make several cuts into an abrasive material like silica brick, asphalt, or a special sharpening stone. This will wear down the metal bond, exposing fresh sharp diamonds and restoring cutting performance. - Using the Right Equipment:

If your power tool lacks the necessary power and RPM, the best solution is to upgrade to a more powerful machine. When choosing a tool, remember that a higher power drive ensures smooth cutting of even the hardest materials. - Ensuring Optimal Cutting Speed:

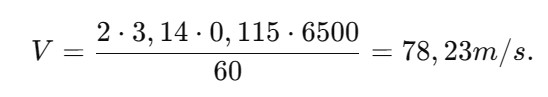

The ideal linear speed for a diamond blade is 80 meters per second. For example, an angle grinder with a 125 mm blade operates at 78.5 m/s, which is close to the ideal value.

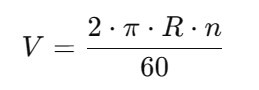

You can calculate the linear speed using the formula:

where:

- V = linear speed (m/s)

- R = radius of the blade (meters)

- n = RPM (rotations per minute)

- π ≈ 3.14 (constant)

For example, calculating the linear speed for a 230 mm blade on an angle grinder running at 6,500 RPM:

which is very close to the recommended 80 m/s.

By following these guidelines, you can ensure efficient and safe cutting with diamond blades while extending the lifespan of your tools. 🚀