Diamond Blades: A Versatile Tool for Cutting Construction Materials

In modern construction and renovation, cutting materials — from concrete to ceramics — is an essential part of the process. To perform these tasks efficiently, diamond blades are widely used. Thanks to their durability and versatility, they have become indispensable tools for both professionals and DIY enthusiasts. Diamond blades are used for a wide range of jobs: cutting materials to size, creating openings, demolition, and more.

What is a diamond blade?

A diamond blade is a circular cutting tool made up of a metal core and a diamond-bearing segment. The cutting part consists of synthetic diamonds known for their hardness and wear resistance. This allows efficient processing of tough materials like concrete, stone, ceramic, and even metal. Manufacturers label their tools and provide clear usage guidelines depending on the target material, making it easier for users to choose the right tool.

Blade construction

A diamond blade consists of two main parts — the steel core and the diamond segment.

Core

Made of high-quality steel, the core supports the diamond segment. Blade diameters can range from 100 mm to over 1600 mm depending on the equipment and application. Some blades feature holes for better cooling and reduced weight. The mounting hole comes in various sizes, from 10 mm to over 60 mm — matching this to your equipment is crucial.

Quality-oriented manufacturers test their blades for balance — unbalanced blades reduce performance and damage equipment. To counter this, heavy areas of the core are often drilled or stamped to restore balance.

Diamond segment

This is the working part of the blade, containing synthetic diamonds bound in a matrix. There are several bonding methods:

-

Electroplated: diamonds are applied using an electrochemical process.

-

Vacuum brazed: diamonds are embedded under high heat and vacuum conditions.

-

Sintered (powder bonded): diamonds are mixed with metal powder and sintered into a durable layer.

Sintered blades are the most common due to their long service life and strength. Vacuum and electroplated blades are best for surface materials like tiles, porcelain, granite, and marble. Sintered blades work well for both finishing and rough cutting — from tiles to reinforced concrete, bricks, aerated blocks, and asphalt.

Types of diamond blades

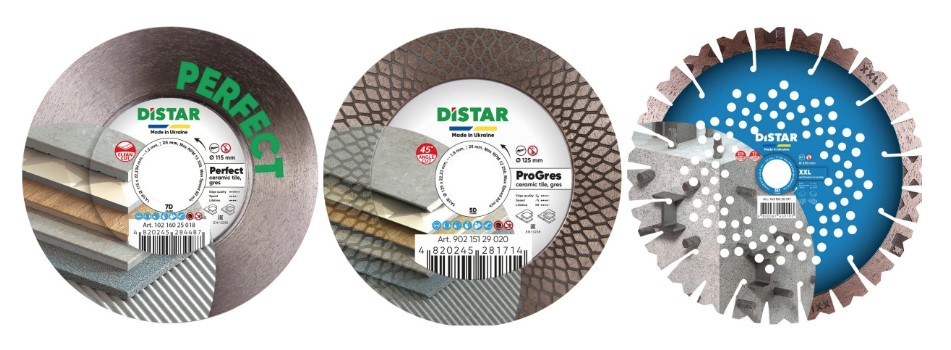

Based on segment design, blades are classified into:

-

Continuous rim – for clean, precise cuts in ceramic, glass, and fragile materials.

-

Turbo – with a wave-like edge that improves cooling and speed; used on concrete, bricks, blocks, paving stones.

-

Segmented – with separate segments for high performance and cooling in tough materials like reinforced concrete and stone.

-

Hybrid – combining features for universal applications.

Using the wrong blade type can lead to damage. For example, using a segmented blade on ceramic can cause chips, while using a continuous rim on reinforced concrete can cause overheating and failure.

Applications

-

Construction: cutting concrete, asphalt, stone, bricks

-

Renovation: ceramic tiles, porcelain stoneware, marble

-

Industry: metal, glass, ceramics

-

Jewelry: shaping precious and semi-precious stones

Advantages

-

High performance and cutting speed

-

Long life thanks to wear resistance

-

Precision cuts without chipping

-

Versatility across many materials

Disadvantages

-

Higher price than abrasive discs — but justified by lifespan

-

Sensitive to misuse — always follow usage guidelines

Selection and use

Consider:

-

Material type (concrete, metal, ceramics)

-

Equipment (grinder, tile saw, cut-off saw)

-

Cutting conditions (dry or wet)

Follow manufacturer’s guidelines for speed, depth, and cooling.

Safety tips

-

Always wear PPE: goggles, gloves, ear protection, respirator

-

Inspect the blade before use

-

Avoid overheating and jamming

-

Ensure proper water flow during wet cutting

Conclusion

Diamond blades are essential tools for cutting and processing materials in construction and industry. Their durability, accuracy, and versatility provide excellent performance and results. Choosing the right blade and following instructions ensures maximum efficiency and tool longevity. If you're looking for reliable diamond tools and accessories, Distar offers cutting-edge solutions at a reasonable price!