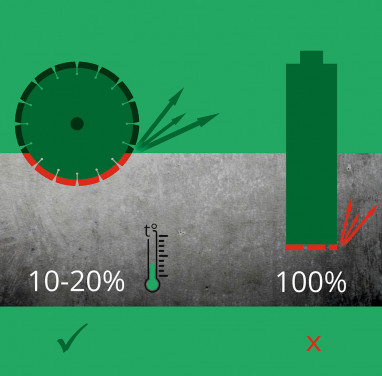

The diamond blade penetrates the material along a short arc, while a longer section of its surface remains exposed to the air, allowing for effective cooling.

26 March 2025

0

In addition to cooling, the blade efficiently expels the cutting slurry from the cutting zone, ensuring an effective cutting process.

Unlike blades, the diamond segments of core drills remain continuously in the processing zone. This prevents intensive cooling, and the deeper the drilling depth, the higher the temperature in the drilling zone. These conditions have led to the widespread use of core drills with water cooling. The water flow not only cools the diamond segments but also effectively removes slurry from the drilling zone, making the process fast and efficient.