Devices 125

58 modelsMechanic devices

The machining of building materials (cutting, grinding, drilling) is accompanied by a considerable amount of dust and sludge.

TM MECHANIC range offers accessories that provide high quality dust and sludge removal from the building material handling area.

Work with ceramic tiles

The most common tool for cutting and deburring is an angle grinder.

Here are the most popular accessories in TM MECHANIC, designed for such purposes.

- Tile cutting. SLIDER 90x125, SLIDER 45x115-125 and DUSTER 45 115-125 are designed for tile cutting at 90 and 45 degrees respectively and can be used with any 125 angle grinder. The SLIDER 90x125 is fitted with a special dust extraction pipe, but the 45 degree cutting device does not have one, but a dust extraction pipe can be purchased separately (see PIPE 45).

The SLIDER 45x115-125 2.0 has its own presetting and is used for mass cuts at 45 degrees. The DUSTER 45 115-125 is the perfect solution for those who are used to manually controlling the cut with as much visibility as possible.

- Tile drilling. Drilling always starts with a marking and if the tiles are not laid on the wall, the holes can be transferred from the wall using the TILETEMPLATE stencil, which are designed in two variations, for small and medium format. This is a very handy template for transferring, for example, a future hole of up to 50 mm in diameter.

After marking, it is very important to drill so that the tiles are not damaged. The EasyFix is the solution to this problem, with which you can start drilling with bore bits up to 70 mm. After drilling to a depth of 3-4 mm, further drilling can be carried out without this device.

The accompanying product, CoolGel, is also very popular. This is a special gel that provides cooling and dust extraction when drilling without coolant.

In addition to wet drilling, there is also dry drilling, and this kind of work generates a lot of dust. For dust-free drilling you can use the HomeDuster (holes up to 20 mm diameter) and the DrillDuster (holes up to 82 mm diameter).

"Mitter cutting" the tiles. This process is also accompanied by dust sludge and in order to minimise dust you can use TileDuster, for which the 115 mm and 125 mm angle grinder are suitable. One of the latest developments for 'miter cutting' is the Click-Lock Uni holder.

This attachment for flexible grinding discs ("turtles") is equipped with magnets, which is attached to the cutting disc and allows you to grind the edge of the tile without removing the disc.

Working with concrete, bricks and other building materials.

Construction tasks with materials such as concrete, bricks, aerated concrete, foamed concrete, etc. are accompanied by even more dust or water (if wet drilling) than work with ceramic tiles, so there are many devices available for these materials as well.

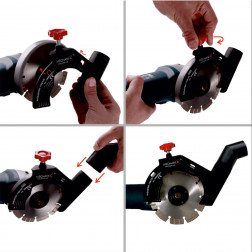

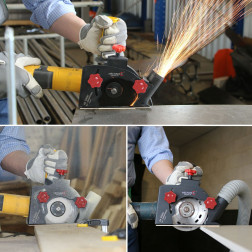

- Cutting. The most popular dust extraction attachments are the AirDuster 115-125 and the AirDuster. They allow you to cut concrete and other construction materials practically dust-free on the 115, 125 and 230 mm angle grinders. There are also upgraded versions of these tools - the AirChaser wall-grooving machine. The difference is that they have special wheels for easy handling and the cutting depth can be adjusted.

- Drilling. The AquaDUSTER 162, is designed to remove water sludge and can be used with diamond drill bits up to 162 mm in diameter. For dry drilling, the dust problem is eliminated with DrillDUSTER 82 2.0 or DrillStream dust extractor. This device is placed between the power tool spindle and the drill bit and extracts the dust from inside the drill bit.

You can find and order these as well as many other accessories at Distar.ua. In addition to the selection of tools, you can also pick up diamond tools that ensure high speed and quality of work.